Collagen is the main component of most tissues and organs in the body but it has proved difficult to produce in the laboratory using 3D printing. A team of researchers at Carnegie Mellon University in Pittsburgh in the US has now developed a new technique that makes use of a support gel to 3D print heart tissue containing collagen. The method, dubbed FRESH (for freeform reversible embedding of suspended hydrogels) can produce parts of the heart at various scales, from capillaries to the full organ. This structure even contracts when made using human cardiac muscle cells.

Although 3D printing (also known as additive manufacturing) has been around since the 1980s, it is only in the last two decades that researchers have used it to fabricate biological cells and structures for applications in regenerative medicine. The technique has recently come along in leaps and bounds with the fabrication of patterned tissues, vascular-like networks that can be perfused with living cells and nutrients, and implantable scaffolds. However, printing living cells and soft biomaterials such as extracellular matrix (ECM) proteins, like collagen, has been difficult.

“Soft and squishy”

“This is because cells and tissue are soft and squishy, which means it is nearly impossible to 3D print them without having them collapse,” explains study leader Adam Feinberg. “Indeed, 3D bioprinting up to now has generally been limited to very thin and tiny scaffolds. In our work we have solved this problem by 3D bioprinting inside a ‘support’ gel that prevents the cells and hydrogels (similar to gelatine) from collapsing.”

With their technique, the researchers say that they are able, for the first time, to 3D print collagen, which is the major structural protein in the body, with the same ease that we can 3D print plastic, metals and other materials. “Being able to do this means that we can now print scaffolds and tissues that actually have biological function,” says Feinberg.

New improved FRESH

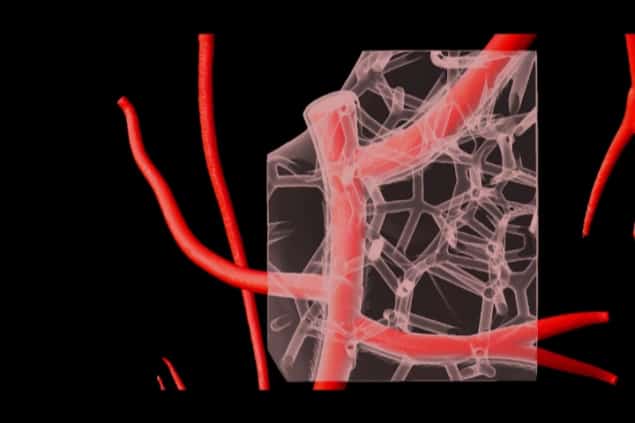

The team first put forward its FRESH technique in 2015 and has now developed a new and improved version that makes use of rapid changes in pH to self-assemble collagen and force it to solidify. The method works by extruding bioinks containing unmodified collagen from a needle in the 3D printer, which contains a special support bath composed of a gelatine microparticle slurry that provides support during printing. The needle extrudes thin layers of collagen and cells and these layers then stack on top of each other to create the 3D object. Once the printing is complete, the researchers raise the temperature from room temperature to body temperature (37°C), which gently melts the support and releases the printed scaffold.

The technique can produce complex structures with functional architectures that can be further embedded with living cells or complex vascular-like networks at printing resolutions of up to 20 microns, say the researchers. Cardiac ventricles printed using human cardiac muscle cells are able to contract synchronously and propagate action potentials in a particular direction – just like a real heart. The heart wall also thickens by up to 14% during the phase of the heartbeat known as peak systole – again similar to the real organ.

Patient-specific anatomical structures

The researchers say they can also create patient-specific anatomical structures: “Here, we start with a magnetic resonance imaging (MRI) or micro-computed tomography (CT) image of a patient’s entire heart or just a component, such as a heart valve,” explains Feinberg. “This allows us to create a 3D computer model matched to the patient. Next, we use the computer to convert the 3D model of the heart valve, for example, into instructions that tell the 3D printer what to do.”

There are currently no other methods to 3D bioprint collagen with the resolution and fidelity that we can achieve with FRESH, he tells Physics World. “Importantly, the technique can also use unmodified collagen, meaning we can print pure collagen and use changes in pH to transform the liquid collagen into a gel. Other methods that have been able to print collagen typically needed to chemically modify the collagen or mix it with other materials to improve printability.”

Read more

Hydrogel bioprinting takes to the air

Broad applications in tissue engineering and regenerative medicine

In their work, which they report in Science 10.1126/science.aay0478, the researchers focused on building the heart and its components. “What is really exciting, however, is that collagen – being the major protein in nearly every tissue and organ in the body – has broad applications in tissue engineering and regenerative medicine,” explains Feinberg. “We have also developed custom bioprinters for FRESH and released the designs as open source hardware that we hope the research community will widely adopt. This will hopefully lead to new research and ultimately treatments for a range of diseases in the years to come.”

The team says that it is now busy continuing to build more complex cellularized models of the heart – initially to understand how heart muscle forms and functions, but also with a view to replacing damaged regions of the heart in the long term. “We are also working on other parts of the body, including building collagen scaffolds to repair damaged skeletal muscle, regenerating the trachea and other tissues, and creating more realistic models of mammary ducts to study and improve treatments for breast cancer.”